CMF Technology

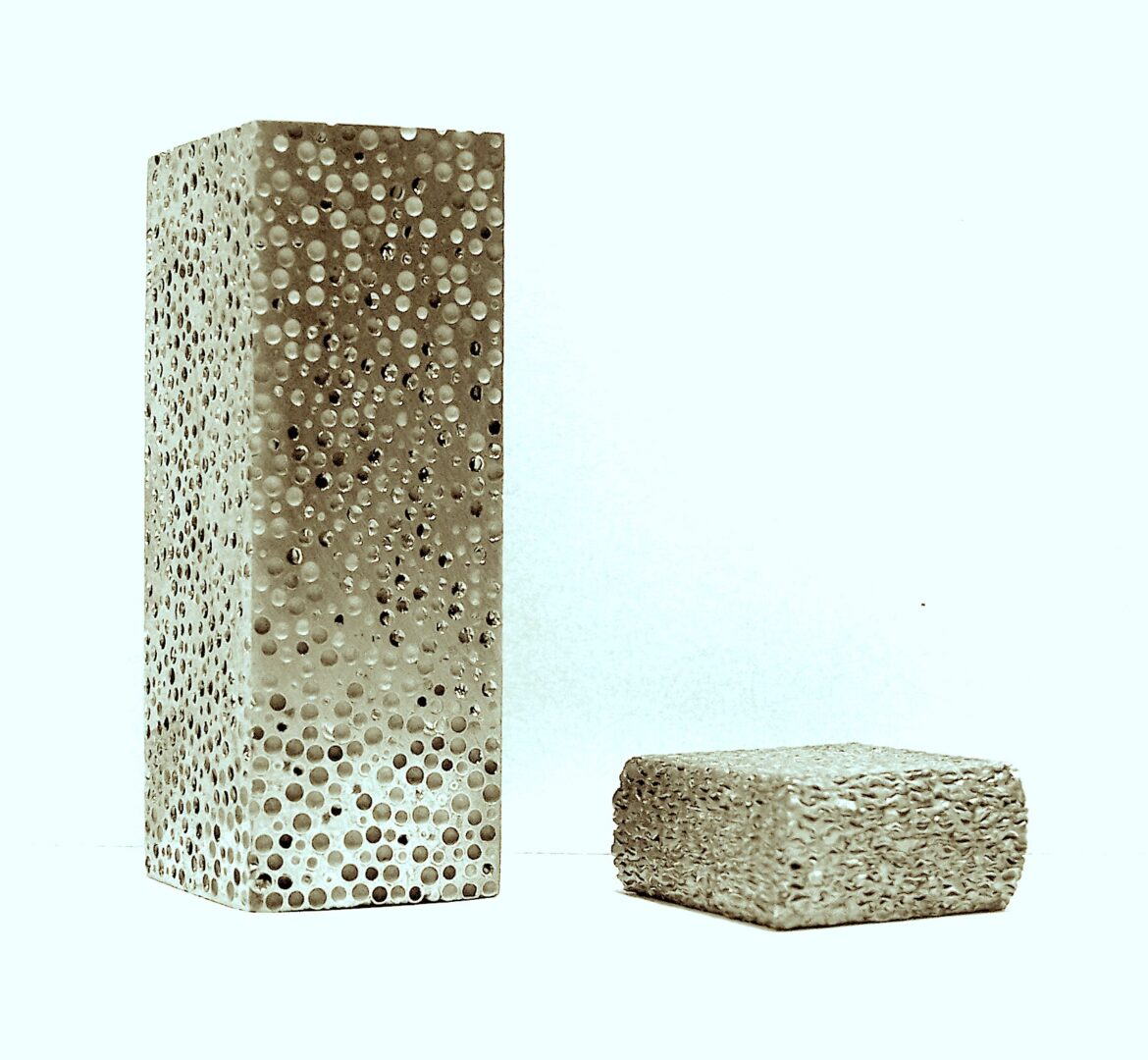

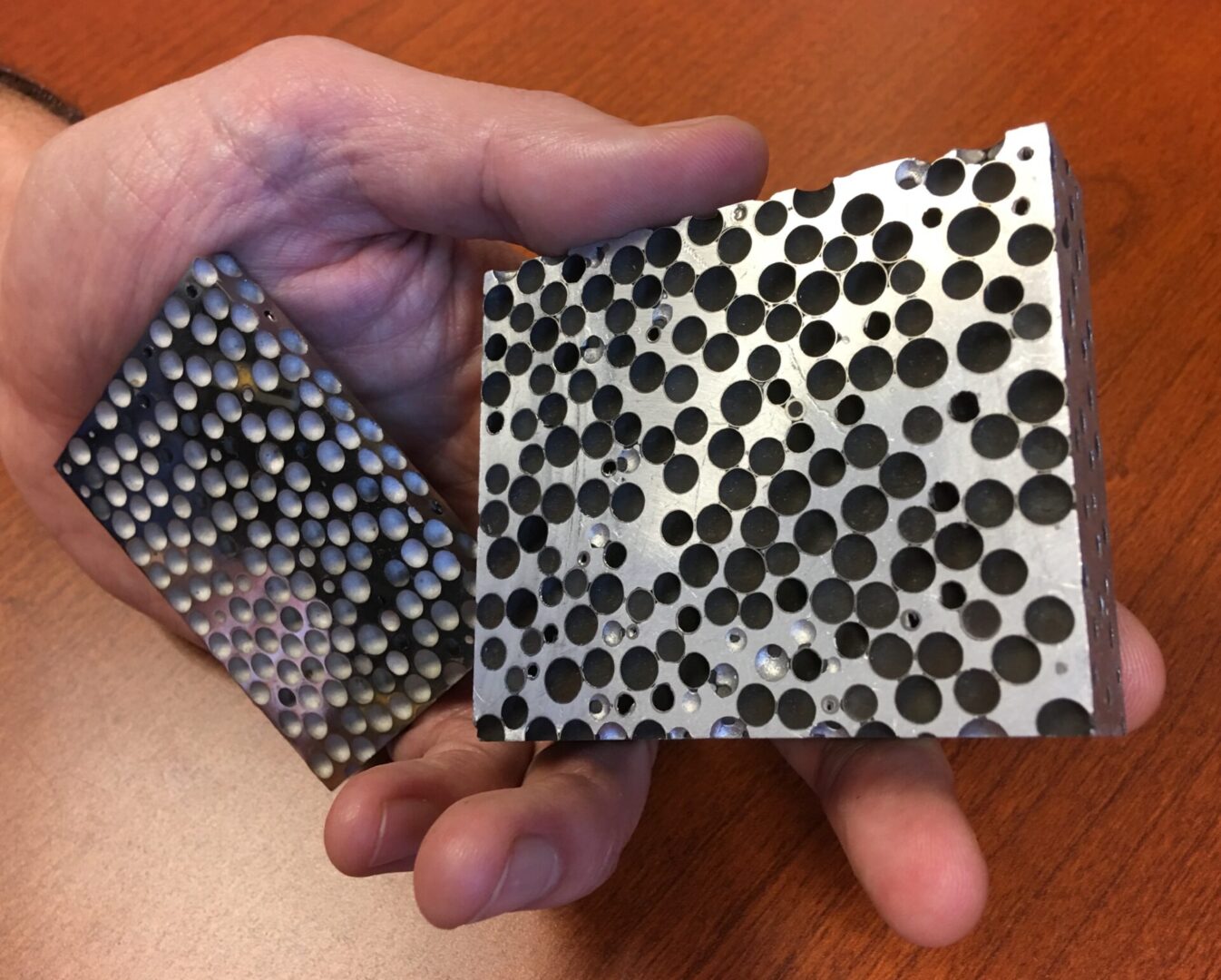

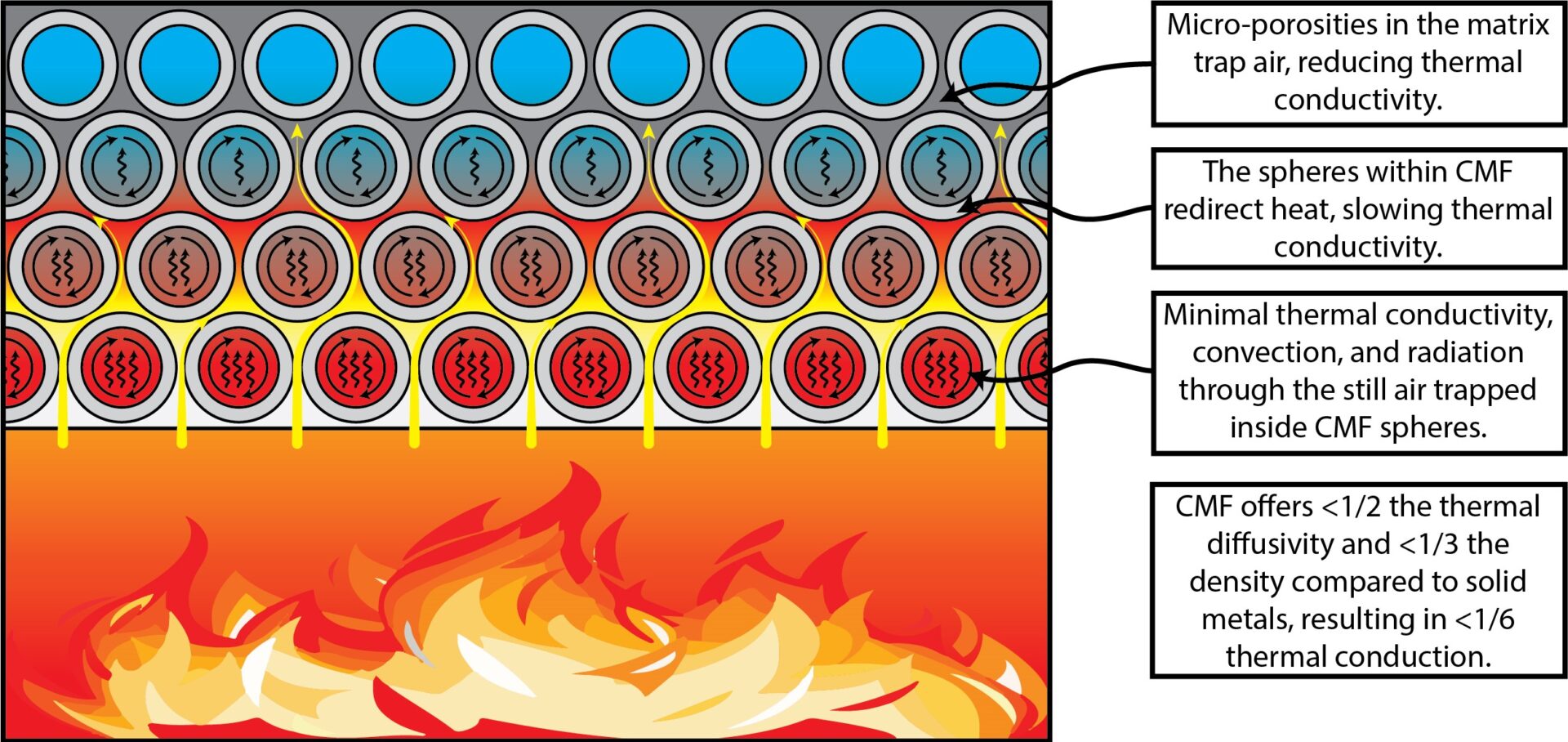

Composite Metal Foam (CMF) is a revolutionary, high-performance, fine-tunable, light-weight class of metallic materials that can be made from any metal, alloy, or combination. Processed via a casting or powder metallurgy technique, this material is a homogenous mixture of hollow, air-filled metal spheres with a metal matrix surround.

A 100% steel CMF bar will weigh the same as an equal-sized solid aluminum bar.

In every combination of hollow metal spheres and matrix materials, the final product weight will be ~65-70% lower than the weight of an equal-sized piece of solid parent material. The air trapped inside CMF's porosities provides these incredible weight savings.

For more information regarding Composite Metal Foam technology, please visit Dr. Rabiei’s website at North Carolina State University, where the technology originated. Visit her website here.

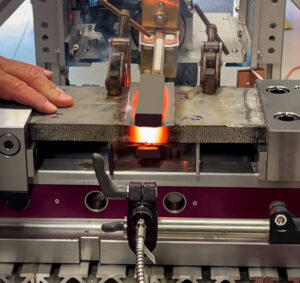

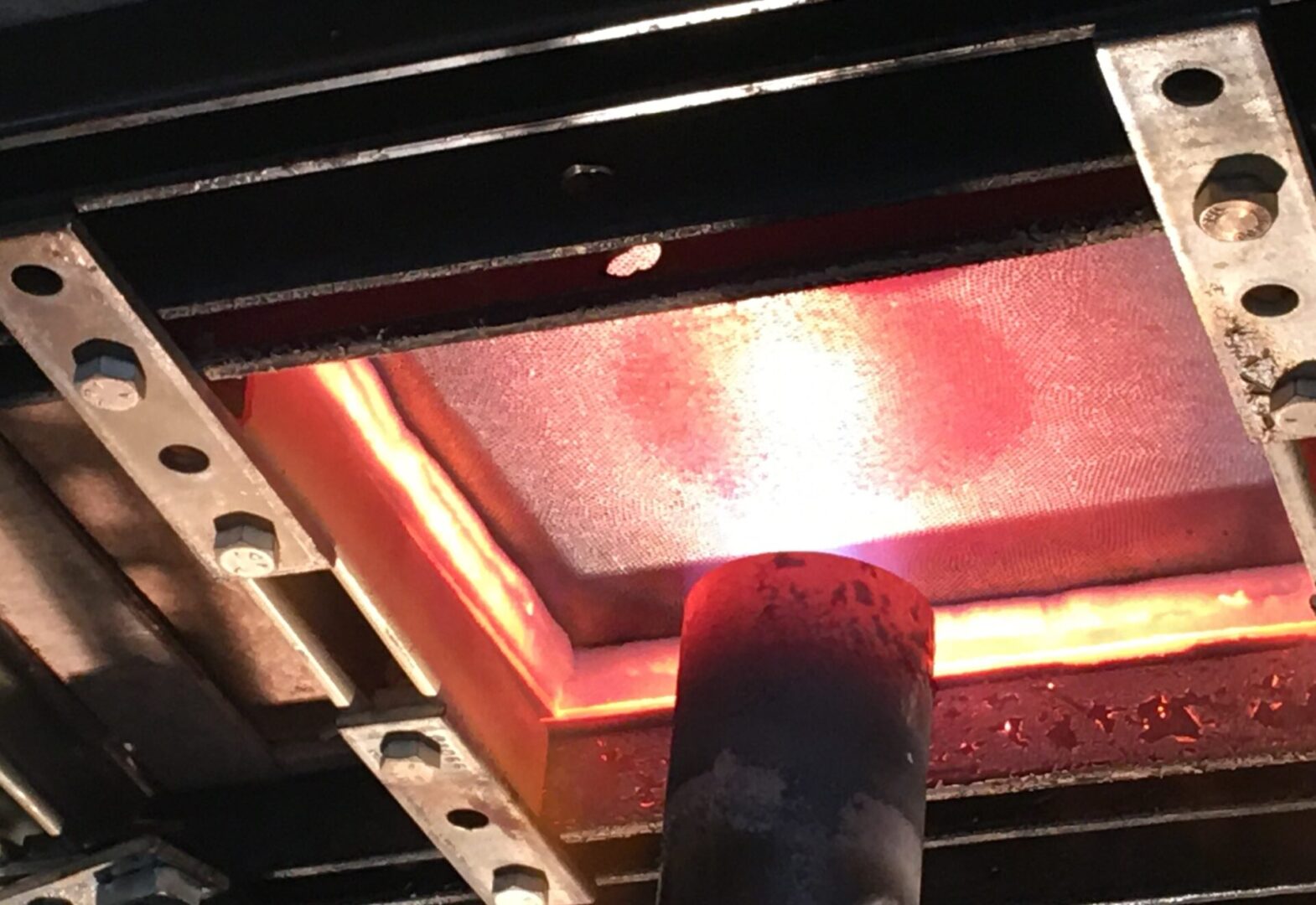

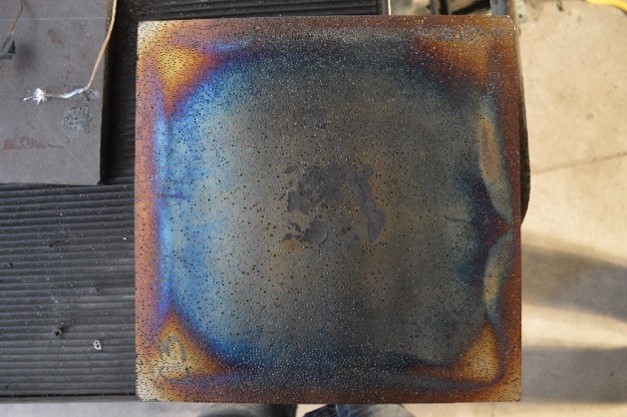

Composite Metal Foam has a world-class ability to prevent heat transfer, burning white-hot at 1,100 C (2,000 F) temperatures while remaining at room temperature and touchable only 2 inches away!

Steel CMF retains its strength and properties, equal to 3 times heavier solid steel, at these extreme temperatures while weighing as little as aluminum, a metal that would melt instantly at these temperatures. The combination of extraordinary abilities to withstand and block these extreme temperatures while remaining lightweight can protect against numerous threats and enhance product performance while saving lives and protecting the environment.

CMF has proven to absorb over 100 times more impact energy than fully solid parent material equivalents. In a 2020 puncture test, a 1" thick steel CMF sandwich panel managed to absorb over 14,500 Joules of energy over only a 1.25" in diameter area of impact.

CMF resists thermal transmission better than fully-solid equivalents. Steel CMF has a coefficient of thermal conductivity of only 3.8 W/m K at 300 C. Compare this to solid aluminum (equal in weight to steel CMF) with a coefficient of thermal conductivity of 205 W/m K, 54 times higher.

In a torch fire test, a plate of steel CMF withstood 1,200 C (2,200 F) temperatures for over 30 minutes without exceeding a backplate temperature of 427 C (800 F). CMF lasted at least 7.5 times longer than a plate of solid parent material that failed the test after only 4 minutes.

CMF materials have shown promise as radiation shields. In a recent test, a block of HZ steel CMF displayed 4 times higher radiation shielding abilities against x-ray and neutron radiation when compared to an equal weight solid aluminum equivalent.

CMF can be made out of nearly any metal, alloy, or combination and in every case, weight savings of ~70% are possible. 316 Steel CMF weighs the same as a solid block of aluminum and Mg-CMF can be made even lighter than water, resulting in a metallic material that can float.

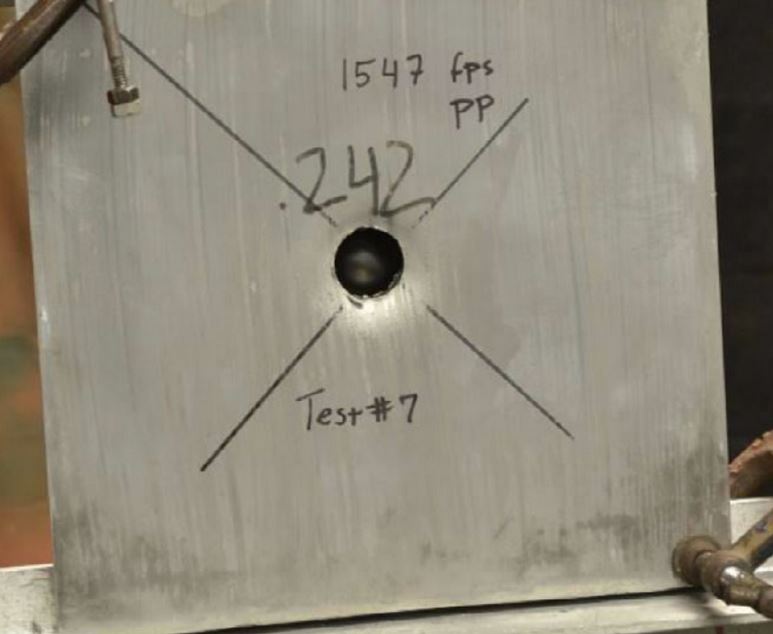

Researchers have demonstrated that Composite Metal Foam (CMF) vehicle armor developed at NC State can stop armor-piercing .50 caliber rounds just as well as conventional steel armor, at less than half the weight. This material will allow vehicle designers to develop lighter-weight military vehicles without sacrificing safety, or improve protection without making the vehicles heavier. Learn more about the test here.

Services

AMM has recently expanded its manufacturing capabilities by adding an extra large CNC machine (Toyoda VB215, capable of machining parts of 79"x 55"), a milling machine, a 200 ton hydraulic press, a large sonic cleaner (capable of accommodating 52″ length x 24″ width x 20″ working depth), a large oven with 6' height, a large shaking table and robotic arm, blast room, paint booth and more. These capabilities will allow AMM not only to manufacture large CMF products but also to provide manufacturing and machining services to customers. Reach out through the contact page if interested in having your large parts manufacturing/machining project quoted and turned into reality here in Raleigh, NC.

Machining Services

- Machining large metal parts up to 5'x5'

- Pressing large parts up to 47" wide

- Sonic cleaning of large parts/materials

- Shaking parts up to 4'x4' footprint

- Sandblasting services on parts up to 5'x5'